- Model

- 138S23-K

- Dimension

- 138×23mm

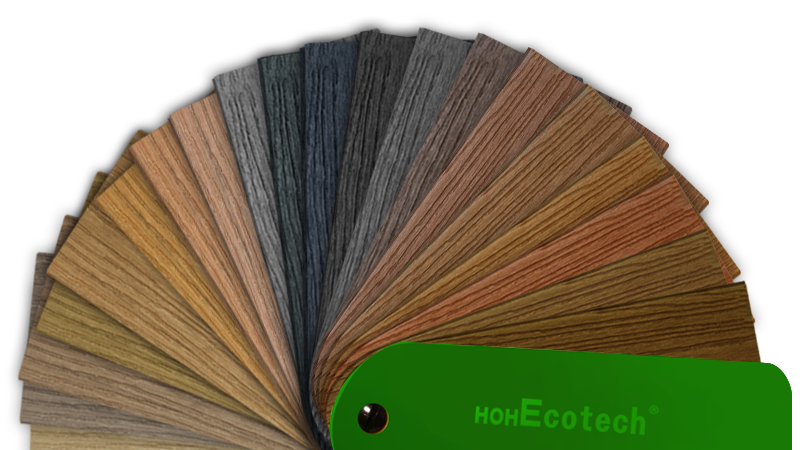

Compared with the other two models, Co-extrusion composite decking has more outstanding performance in all aspects and is better than the previous two models. Not only does it have a high level of protection in all aspects (mildew-proof, fire-proof, moisture-proof, moth-proof, and crack-proof), it also has lower maintenance costs. Its strong anti-ultraviolet performance can make the color difference between the front and back almost invisible to the naked eye after being exposed to strong ultraviolet rays for 2,000 hours. Co-extruded products can be produced in two colors and two designs (different textures can be selected on the two planes), allowing you to enjoy the freedom of multiple choices.

+86-13955981177